The product complies with the European Directive 89/686, notably regarding ergonomics, innocuousness, comfort and with standards :

PIGMENTED SPLIT LEATHER SHOES – S3 SRC

Upper: Pigmented split leather, S3 water resistant treatment. Lining: Polyamide mesh. Insole: Removable preformed – Polyamide on EVA. Outsole: Injected – PU bi-density.

1-Flex-Zone

2- V STAB SYSTEM3- Ladder lateral grips

4- Cleats with grip on all indoor and outdoor surfaces

5- Standards SRC

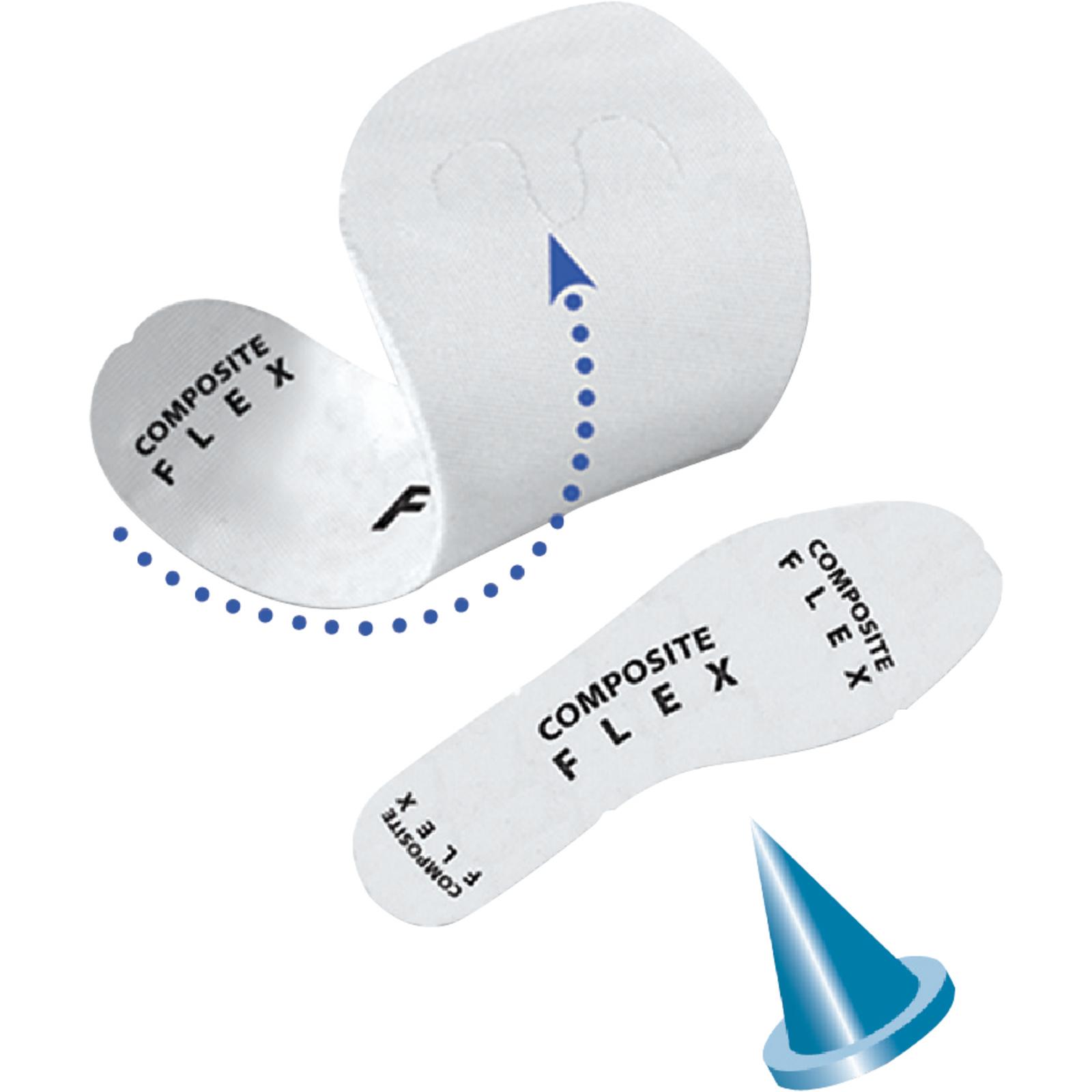

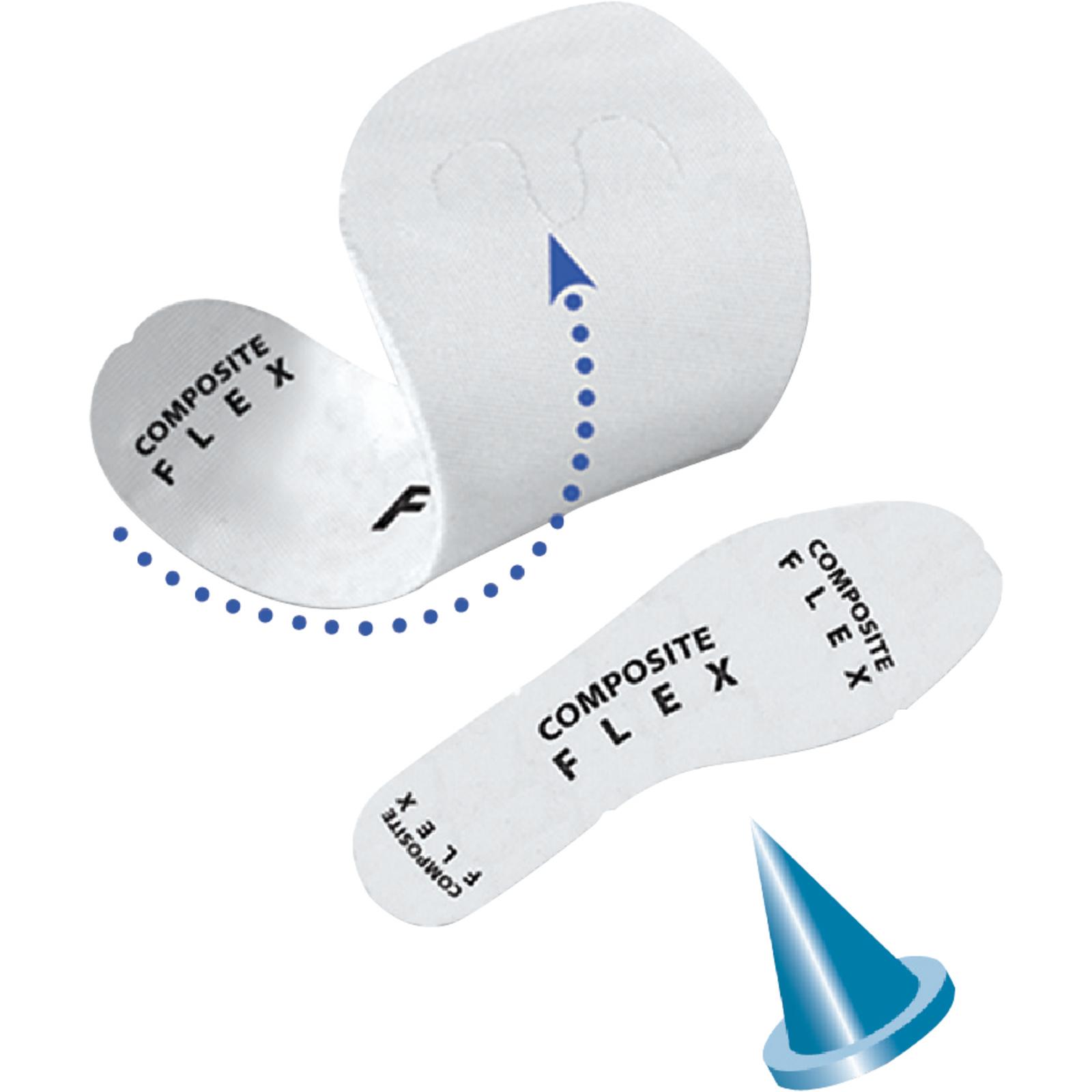

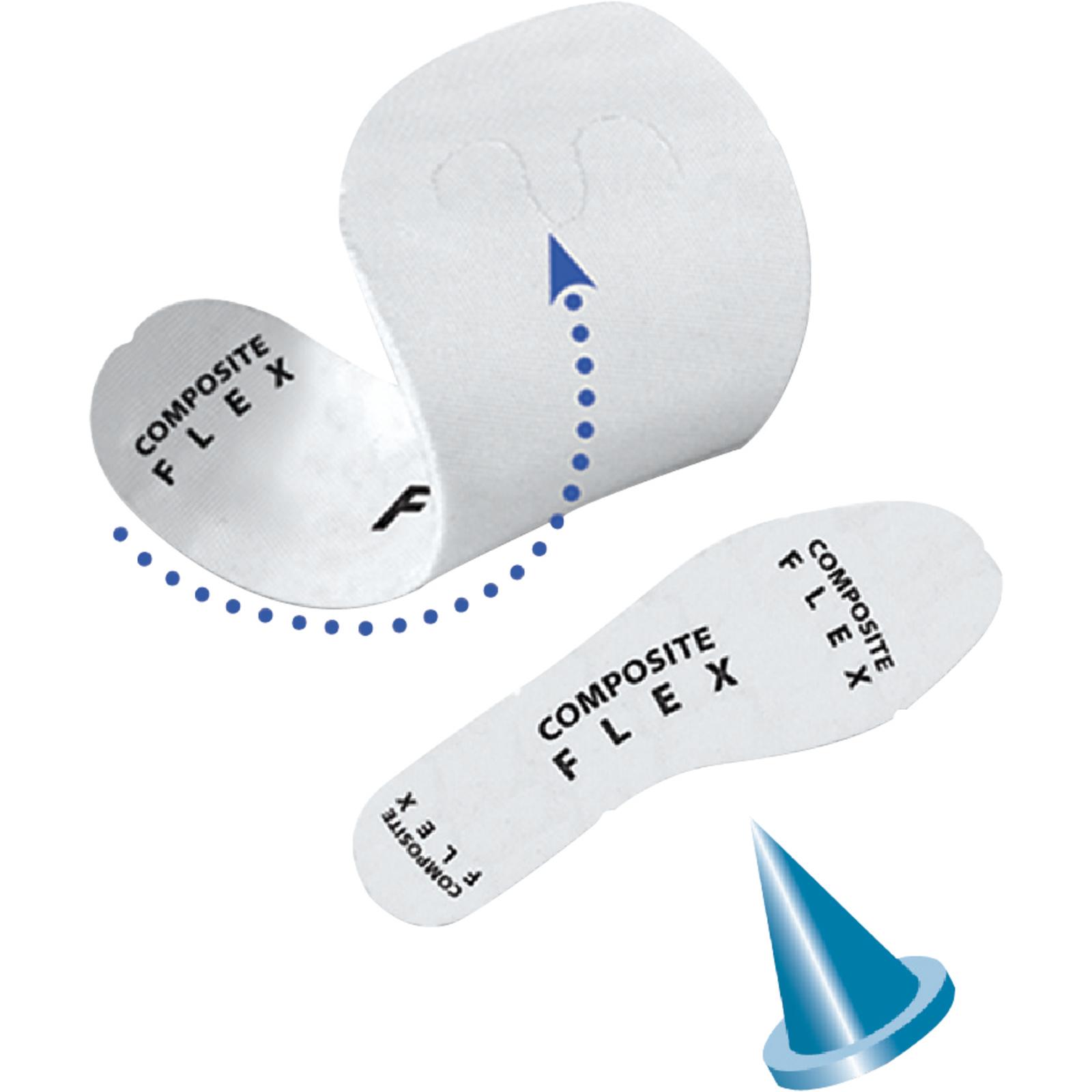

Ultra flexible anti-perforation composite insole

NON-MAGNETIC

No metal part in the shoe

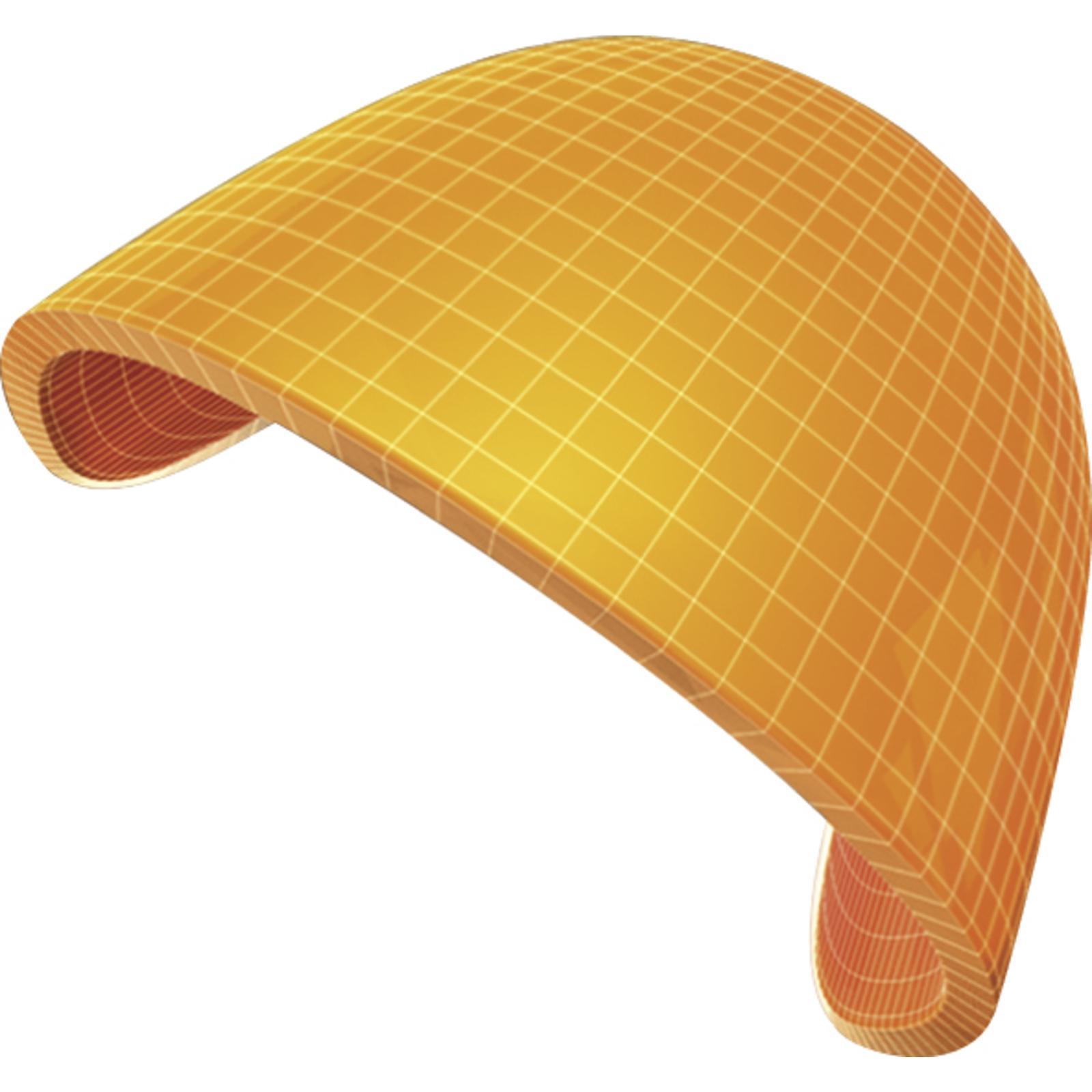

Composite toe cap 200- joule,

Lighter than steel

Non conductive material

NON-METALLIC

Speed lace

| Reference |

pcb |

Colour |

Size |

| PHOCES3NO36 |

5 |

Black |

36 |

| PHOCES3NO37 |

5 |

Black |

37 |

| PHOCES3NO38 |

5 |

Black |

38 |

| PHOCES3NO39 |

5 |

Black |

39 |

| PHOCES3NO40 |

5 |

Black |

40 |

| PHOCES3NO41 |

5 |

Black |

41 |

| PHOCES3NO42 |

5 |

Black |

42 |

| PHOCES3NO43 |

5 |

Black |

43 |

| PHOCES3NO44 |

5 |

Black |

44 |

| PHOCES3NO45 |

5 |

Black |

45 |

| PHOCES3NO46 |

5 |

Black |

46 |

| PHOCES3NO47 |

5 |

Black |

47 |

EN ISO 20344:2011 Personal protective equipment - Test methods for footwear This standard defines the test methods for safety footwear, protective footwear, and occupational shoes.

It may be used only in conjunction with standards EN ISO 20345 and EN ISO 20347, which specify the requirements for the shoes as a function of specific levels of risk involved.

EN ISO 20345:2011 Personal protective equipment - Safety footwear. - S3 Additional special requirements

- SRC Slip resistance

In reference to standard EN ISO 20344, this European standard defines the basic and the additional (optional) requirements for safety footwear for the workplace, marked «S».

The safety shoe is equipped with safety toe caps designed to withstand a maximum impact of 200 joules and crushing up to 15 kN.